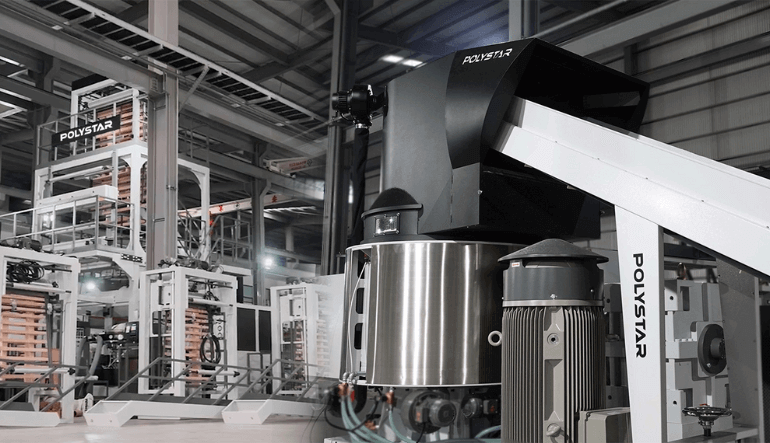

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

ADVANTAGES OF ABA CO-EXTRUSION BLOWN FILM MACHINE

A co-extrusion process uses more than one polymer to form the plastic bubble and therefore more layers to the film. The most prevalent blown film process today is the ABA co-extrusion process. One of CHYI YANG's most popular machines is also the ABA co-extrusion blown film machine. The term ABA indicates the three-layer structure of the film, two outer layers, and one inner layer, hence ABA. The materials of the A layer and B layer are different. The outer layer typically uses new materials, whereas the inner layer uses recycled materials. Using more than one material leads to several advantages and installation adjustments on the ABA blown film machine. As a leading plastic film machinery manufacturer in Taiwan, today CHYI YANG will talk about the advantages of this kind of blown film machine and how it can help your business.

Máquina de Película Soplada ABA - ¿Cuál es la ventaja?

Para la producción de bolsas de PE, la máquina de película soplada de una sola capa ha sido la más utilizada. Probablemente sigue siendo la mejor máquina para productos como las bolsas de frutas y verduras (bolsa perforada en rollo) en las que se utilizan principalmente materiales vírgenes con un espesor de película reducido que va de 6 a 15 micrones. La máquina de una sola capa es también la opción preferida para la producción de bolsas biodegradables.